4.1. 1-D Problems

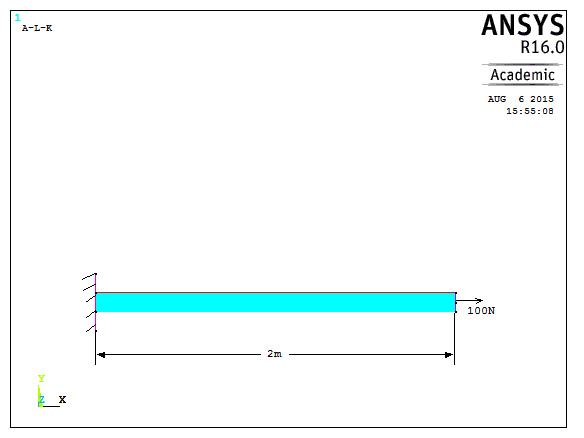

W1: Consider a 2m long steel bar of 50mm2 cross sectional area as shown below. Use two element mesh to model this problem. Find nodal displacements, element stresses and reaction. Take Young’s modulus, E=2x105 N/mm2, load=100N.

Data: Length of bar=2000mm, Cross sectional area=50mm2, E=2x105 N/mm2, Load=100N

Sol:

Preprocessing

- Change jobname

File> Change Jobname

Enter ‘Bar with end load’’ and click on ‘OK’.

- Define element types

Preprocessor> Element Type> Add/Edit/Delete

Click on ‘Add..’, highlight ‘Link’, then ‘3D finit stn 180’, click on ‘OK’, then ‘Close’.

- Define the cross sectional area for the Link180

Preprocessor> Sections> Link> Add

Type ‘1’ for ‘Add Link Section with ID’. Type ‘Bar’ for Section Name’. In this problem, the area is 50. Fill in the Link area value. Choose ‘Tension’ for ‘Tension Key and click on ‘OK’, then ‘Close’.

- Define Material Properties

Preprocessor> Material Properties> Material Models> Structural> Linear> Elastic> Isotropic

‘OK’ for material set number 1, then enter 2e5 for EX, then ‘OK’.

- Create nodes at bar nodes

Preprocessor> Modeling> Create> Nodes> In Active CS

Enter 1 for node number (ANSYS would automatically number nodes if this column is left blank). Enter the location as (X,Y,Z)=(0,0,0). Click on ‘Apply’. Continue defining nodes 2 & 3 using the locations based on the sketch of the bar, but after entering the node 3 location, click on ‘OK’ instead of ‘Apply’. So, node 2 is at (X,Y,Z)=(1000,0,0) and node 3 is at (X,Y,Z)=(2000,0,0).

As a check to ensure all nodes were entered correctly, list the nodes.

Utility Menu> List> Nodes

Turn on node numbering.

Utility Menu> PlotCtrls> Numbering

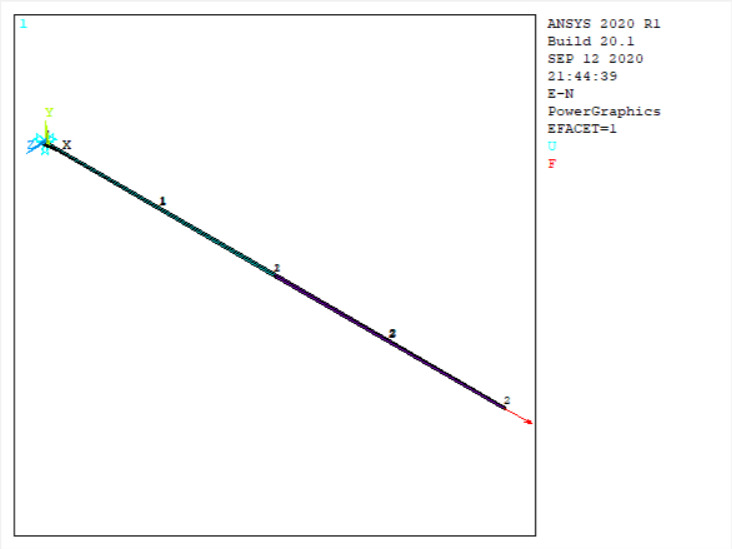

- Create link elements between nodes

Preprocessor> Modelling> Create> Elements> Auto Numbered> Thru Nodes

A picking menu appears. Pick node 1, then node 2 and click on ‘Apply’ in the Picking Menu. Pick node 2, then node 3 and click on ‘OK’ in the Picking Menu.

- Apply constraints and forces on the model.

Solution> Loads> Apply> Structural> Displacement> On Nodes

Pick node 1, then click ‘OK’ in the picking menu that has appeared. Choose ‘ALL DOF’ and use the default displacement value of zero.

Apply the forces.

Solution> Loads> Apply> Structural> Force/Moment> On Nodes

Pick node 3, then ‘OK’ in the picking menu, choose ‘FX’ as the direction of the force, and enter 100 for the force value. Click on ‘OK’.

Solution

- Solve the problem

Solution> Solve> Current LS

Click ‘OK’ in the ‘Solve Current Load Step’ Box

Postprocessing

- Plot the deformed shape

General Postproc> Plot Results> Deformed Shape

Choose ‘Def + undeformed’, then ‘OK’

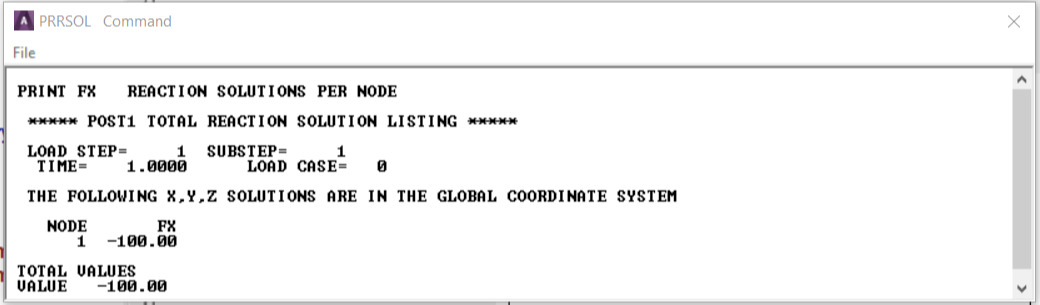

- List reaction forces

General Postproc> List Results> Reaction Solution

Click on ‘All struc forc F’, and ‘OK’

Print the information in the Listing Box, by clicking, in that box, on File> Print. Or else, just write the information down.

- List a summary, which includes the axial force and stress in each element

General Postproc> List Results> Element Solution> LineElem results> Structural ELEM

Click ‘OK’, and a summary for each element is printed, including the node numbers, from which the corresponding bar element can be identified, and also the axial force (MFORX), and the axial stress (SAXL). Record or print, this information.

- List the x and y direction deflections for each node.

General Postproc> List Results> Nodal Solution> DOF Solution> ALL DOFs

Click ‘OK’. Again, record or print, this information.

- Exit ANSYS

Quit> Save Everything> OK